|

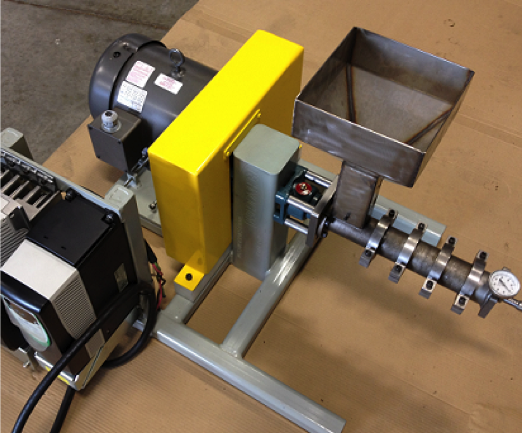

Mini-Extruder

Mini-Extruder is a miniaturized extruder to “cook” oil-seeds by creating friction. The Mini-Extruder is driven by a 7.5 HP motor and can process about 110 lb (or 50 kg) of whole soybeans per hour. While the machine can process many types of oil-crops and grains, the capacity depends upon the bulk-density, moisture and oil content, and the desired temperature profile. Soybeans or other seeds are processed in an extruder to produce extruded or “cooked” meal. The extruder does not typically remove any oil; hence, the extruded meal is called “Full-Fat” meal. The “Full-Fat” meal contains protein, fiber, moisture and oil. Oil can be expelled from the seeds or extruded meal by using a Mini-Expeller. When oil is removed, the meal becomes protein and fiber-rich. It still contains some oil; hence, expelled meal is called “Partially defatted” meal. What does the Mini-Extruder do? 1. Mini-Extruder produces Protein Meal. The main purpose of using Mini-Extruder is to reduce “allergens” or “enzymes” to render Protein Meal edible for humans and animals. Conventional methods of reducing allergens involve steam-cooking or roasting. In addition, such methods require elaborate array of equipment and space. Mini-Extruder uses mechanical energy to create heat rather than subject the seeds to indirect heat. By avoiding steam or heat, the process is clean, convenient, and efficient. 2. Mini-Extruder is employed to rupture oil-cells in oil-seeds and kernels so that the oil can be pressed out easily. 3. Mini-Extruder is employed to reduce moisture in seeds so they can be stored for a long time without deteriorating oil quality. 4. Mini-Extruder is employed to blend two or more grains, oil-seeds, or other ingredients (including spices) to cook them into ready-to-eat food preparations.

Mini-Extruder is ideal for research organizations as well as food and feed companies, who can use the Mini-Extruder to create recipes, test new seeds, and improve process parameters before employing them on large-scale plants. |

||||

|

||||

What is a Mini-Extruder?

What is a Mini-Extruder?