What is a Mini Extruder?

What is a Mini Extruder?

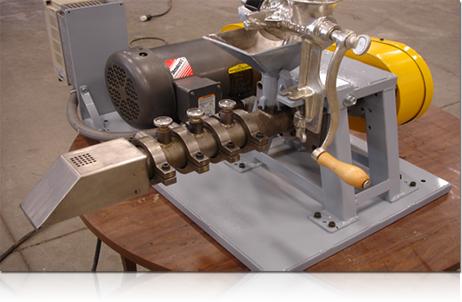

A mini-extruder is a miniaturized extruder to cook a variety of oil-seeds or kernels by creating friction by using mechanical energy. It is a single-screw machine that grinds the seeds which creates friction and cooks the seeds. The Mini uses 7.5 HP and can process about 50 kg of whole soybeans per hour. While the machine can process many types of oil-crops and grains, the capacity depends upon the bulk-density, moisture and oil content, and the desired temperature profile.

Why was the Mini developed?

The Mini was developed by Triple F., Inc. of Des Moines, Iowa under a grant from NASA. NASA’s goal was to employ this technology to prepare high-protein instant foods for astronauts in future space programs. NASA also wanted the technology to benefit humans on earth. Triple F., Inc. granted a license to Technochem to commercialize this technology on earth.

Has the Mini been tested?

The mini-extruder has been tested extensively at Triple F., Inc., as well as the Food Science Department at Purdue University, as co-developers of the Mini under the NASA grant. Subsequent to acquisition of the licensing agreement, Technochem has continued its development and testing.

Why a Mini Extruder?

The Mini is ideal for research-oriented applications. Oil Mills, research organizations, food and feed companies can use the Mini to create recipes, test new seeds, improve process parameters before running them on their commercial scale plants. The Mini is also ideal for creating small start-up businesses at a “Community” or “Village” level in developing countries. Business can transition into larger-scale plants upon achieving success with securing inputs and markets for finished products.